Exercising the hierarchy of control in construction

Construction is one of the most important industries in the world. It ensures continuous growth and development of each country around the world, so it comes as no surprise that the UK construction industry was worth roughly 122 billion last year alone.

Within construction, however, there is a lot that needs to be done to achieve success with every project. This involves time management, the ordering of materials, completing tasks and most importantly keeping employees safe.

In 2020/21, there were 142 deaths in the workplace with the most common industry being construction. There is a lot that can go wrong. From falling materials to slips, trips and falls which is why the right personal protective equipment is needed to keep all staff safe on the construction site.

Ensuring everything goes swimmingly will come down to effective leadership and to have this, you’ll need to exercise the hierarchy of control. Read on to find out what it is and how you can use it on your construction site.

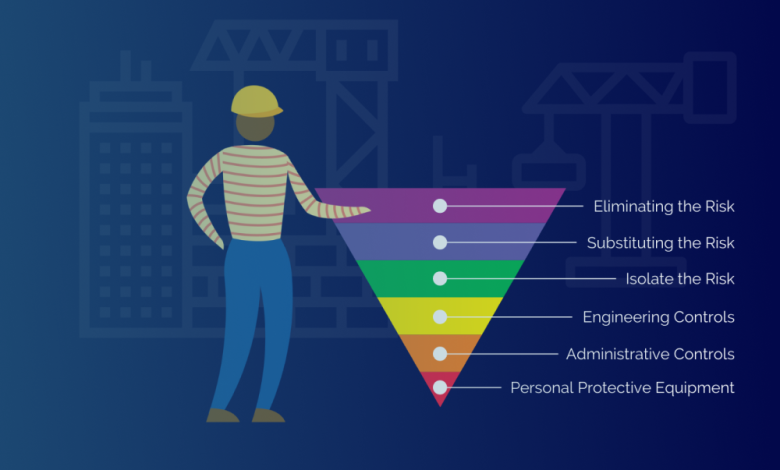

What is the hierarchy of control?

The hierarchy of control is used to mitigate risks in dangerous places such as construction sites. It harnesses 5 different features that site managers can do starting with the most effective to the least effective. Find out what they are below from most effective to least effective.

Elimination

Whilst preparing for hazards is a good method, the most effective thing to do would be to simply take them away from the site altogether. Remove hazards such as wires for people to trip over and see your risk level reduce dramatically.

Substitution

This follows on from elimination. Often to eliminate a threat, it must be replaced. In construction, this could mean eliminating old procedures that are deemed unsafe and replaced by new ones that will put workers in a position of less risk.

Engineering controls

This is all about reducing each worker’s exposure to hazards. This could be through removing the hazard completely or placing a barrier between workers and risk so they do not come into contact with it. The downside to this method is the high cost to set it up. Examples of this include putting fencing up around electrical gear to reduce the risk of human contact with it.

Administrative controls

This is done to ensure workers know how to keep themselves safe at work thus eliminating a lack of knowledge of the site. This could be through training programmes or an induction to the site where staff can be educated on how to keep safe. The downside to this is staff may forget everything they’re told.

Personal Protective Equipment

This is the least effective method but very much a last resort to keeping your staff safe should the risks occur. For a construction site, you can expect to see the following equipment:

- Gloves

- Hard hats

- Safety shoes and boots

- Safety glasses/face shields

- High visibility clothing

- Respirators