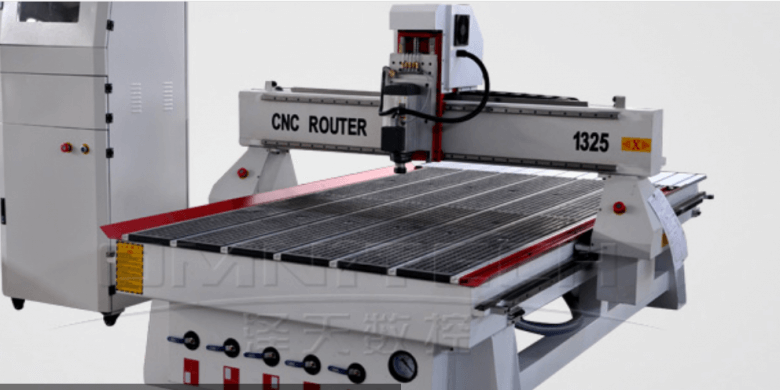

Buying Guide for CNC Woodworking Machines and Routers

If you don’t have the time to manually carve wood, a Computer Numerical Control (CNC) machine is a need, whether you’re a woodworker on the side or a carpenter with a small company that specializes in carving exquisite wood furniture.

If you run a busy shop, these CNC machines can help you save time and the laborious task of manually engraving or carving features into the wood.

Since not all CNC tools are created alike, selecting a proper CNC machine for each work is crucial. Some CNC machines feature operating systems that may not work with certain computer types, while others have less user-friendly operating systems.

Other machines, however, can engrave multiple materials, like plastic, soft metals, or acrylic, which may be useful for a variety of tasks. The truth is that a small shop needs the proper CNC router to function properly.

What qualities distinguish a superb CNC router for woodworking, and which CNC router kit is the best for various skill levels?

Review the buying guide below to learn more and to have a better understanding of the extra features that are frequently included on CNC cutting machine before spending a lot of money on one.

Processor

The three axes (X-axis, Y-axis, and Z-axis) CNC machine comprises numerous spindle speeds, tiny CNCs, and YZ machines, and is the most popular tool because of its affordability and accuracy.

The spindle maintains its position while in operation, making it an excellent CNC equipment for beginners or students.

4-Axis

The three axes of a 4-axis router are combined with an A-axis, which enables the spindle to move left and right while processing three surfaces simultaneously to produce planar and three-dimensional engraving.

This tool is perfect for creating intricate 3D items and patterns out of wood or even soft metals.

Rotating axes

The rotating spindle tool used by CNC routers enables them to treat four surfaces at once. This is especially helpful for cylindrical projects like detailed furniture accents or ornate wooden statues that will be finished in three dimensions.

Motor

Servo and stepper motors are the two types of motors used in CNC equipment.

A servo motors

The servo motor can cut wood precisely, withstand high speeds, and withstand overload for a longer-lasting tool. It’s also steadier and more silent, making it perfect for detailed designs. The CNC tool will be more productive the faster the motor spins.

Stepper motor with Motorized steps

The stepper motor is the less expensive option and works well for simple plane engraving. Stepper motors are trustworthy, accurate, and simple to regulate. They perform well for the majority of woodworking projects as well.

Screw drive and rack drive are two different types of transmission drive systems used in CNC router machines.

Screw Drive

With slower speeds and shorter tool life, the screw drive is the more fundamental of the two. The screw drive may grow loose and require frequent tightening if improperly placed. Smaller wood carving projects generally employ this kind of motor.

Drive-by Rack

The rack drive offers a considerably more precise transmission and is capable of handling more complex tasks. This drive is more costly, lasts longer, and is speedier. For efficient engraving depth, a laser module can employ this kind of drive.

Spindle

Spindles can be air-cooled or have a water-cooling system.

Spindle cooled by air

An air-cooled spindle is less expensive, simpler to maintain, and more user-friendly because it merely employs a fan to cool the spindle down.

spindle chilled by water

When the spindle speed is too high, a water-cooled system uses water to cool the spindle down. In general, it lasts longer, is more accurate, and is quieter than a fan-cooling system.

Table and bed sizes

Two different types of tables are included with router tables: an aluminum table and a vacuum table.

Aluminized tables

The metal table works well for projects that are cylindrical or have other unusual shapes, although it does require that items be secured to the table.

tabletop vacuums

A vacuum table removes the need for clamps by vacuuming the part right onto the surface. Since there is less trembling when in use, engraving may be done with more precision.

Collection of dust

When it comes to cleanup, having a dust collecting system on one of these machines is a wonderful benefit. A dust port on some CNC machines enables the tool to collect dust during carving.